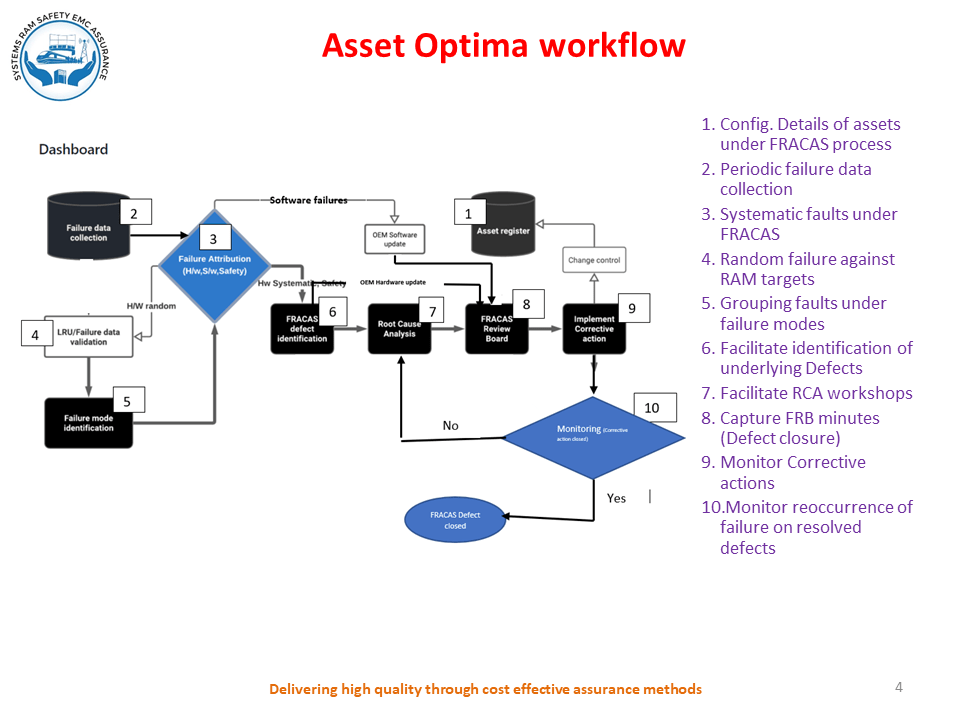

FRACAS Process steps implemented by Asset Optima are –

All the failure in the system are collected in failure data register from the client failure database.

The failure modes for all the failures are identified and classified as hardware/software/system. All the systematic defects are identified according to the MTBF performance.

The systematic defects with common failure modes are identified as FRACAS defects. In the FRACAS defect workshops, the owners of systematic defects are updated by the supplier.

In the root cause analysis workshops, the causes and sub cause of the FRACAS defects are identified using fish bone diagrams

All the software defects are sent to OEM for software update. All the subsystem requiring hardware update are sent to OEM after root cause analysis.

FRACAS review board minutes of meeting, meeting actions, actionee, due date and action status are managed in this form. For a given LRU type the failure performance is obtained graphically.

Corrective action is implemented for the FRACAS defects and all changes are recorded under change control process and recorded into asset register.

All the FRACAS defects ,root causes are monitored for analyzation of any failure.

The defect are closed after authorisation by FRACAS review board

All the failure in the system are collected in failure data register from the client failure database.

The failure modes for all the failures are identified and classified as hardware/software/system. All the systematic defects are identified according to the MTBF performance.

The systematic defects with common failure modes are identified as FRACAS defects. In the FRACAS defect workshops, the owners of systematic defects are updated by the supplier.

In the root cause analysis workshops, the causes and sub cause of the FRACAS defects are identified using fish bone diagrams

All the software defects are sent to OEM for software update. All the subsystem requiring hardware update are sent to OEM after root cause analysis.

FRACAS review board minutes of meeting, meeting actions, actionee, due date and action status are managed in this form. For a given LRU type the failure performance is obtained graphically.

Corrective action is implemented for the FRACAS defects and all changes are recorded under change control process and recorded into asset register.

All the FRACAS defects ,root causes are monitored for analyzation of any failure.

The defect are closed after authorisation by FRACAS review board